[Material Info] Explosion Welding vs. Roll Bonding: Which Stainless Steel Clad Plate Is Best for Your Project?

2025.05.23

Choosing the right stainless steel clad plate is crucial for high-performance industrial equipment. Two of the most widely used manufacturing techniques are explosion welding and roll bonding. Both methods produce metallurgical bonds but differ in their process, product characteristics, and applicable scenarios. Understanding these differences will help engineers, procurement managers, and project leaders select the most suitable clad material solution for their needs.

Method - Explosion Welding Bonding

Explosion welding, also known as explosive cladding, uses the energy from a controlled detonation to bond two metals together. This solid-state technique does not involve melting but instead relies on high-velocity impact to create a metallurgical bond with a wavy interface structure.

How It Works

A flyer plate (cladding material) is accelerated toward a base plate (typically carbon steel) by explosive force. The extreme pressure and velocity result in plastic deformation, jetting, and localized surface melting. These effects create a strong, mechanical and atomic bond with a characteristic wave-like interface.

Advantages

Strong Bonding Between Dissimilar Metals

Explosion welding is highly effective in joining metals with different melting points and mechanical properties, such as stainless steel to carbon steel, or titanium to copper.

Minimal Heat-Affected Zone (HAZ)

As no large-scale melting occurs, the original mechanical properties of each material are preserved.

High Bond Strength

The process creates a solid, reliable bond that performs well under high pressure and in corrosive environments.

Challenges

Explosion welding can create an uneven bond interface. The intense pressure may cause localized melting and splashing, forming vortex-like structures in the bond zone. These areas, while strong, may lead to non-uniformity and complicate downstream welding. Additionally, the environmental impact and safety concerns associated with using explosives limit where and how this method can be applied.

To address shape and surface inconsistencies, post-explosion hot rolling is often used to improve flatness and control the final mechanical properties.

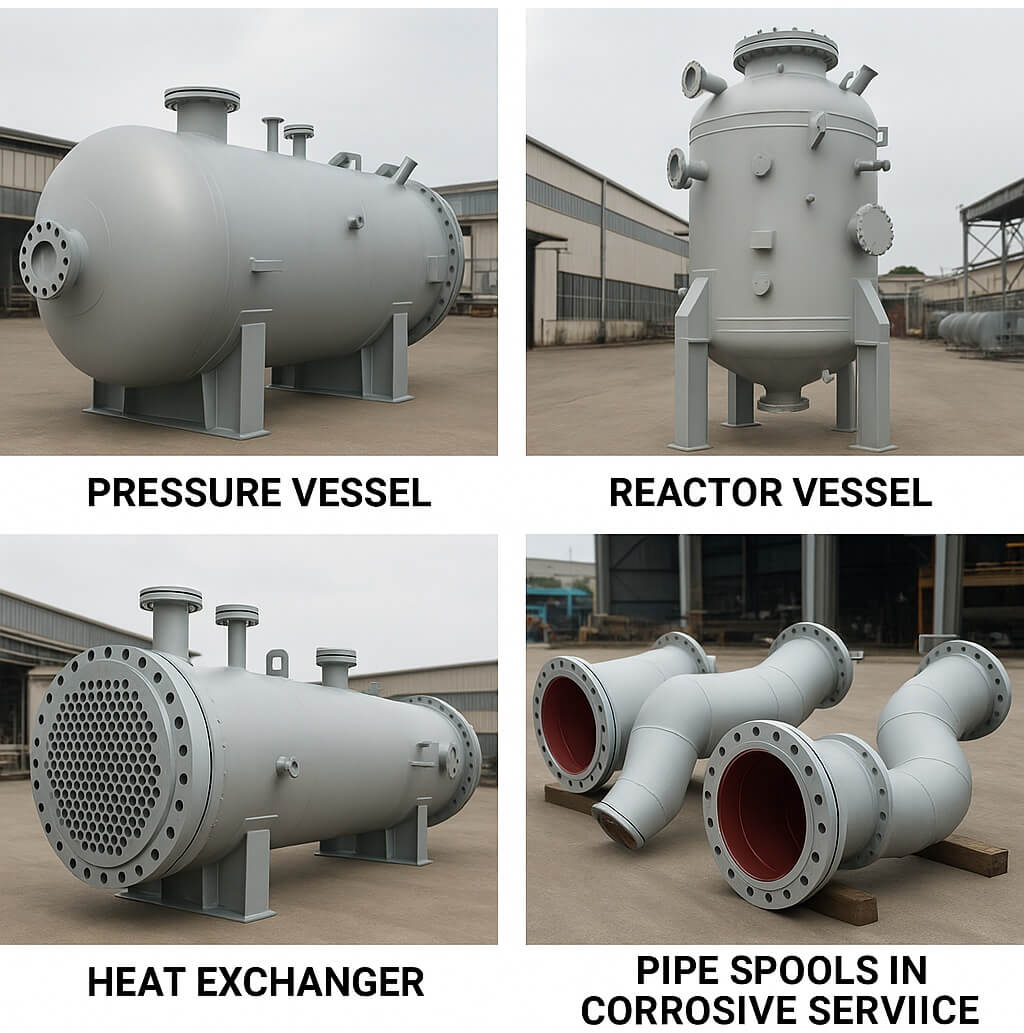

Applications of Explosion Welded Stainless Steel Clad Plates

Pressure vessels

Reactor vessels

Heat exchangers

Pipe spools in corrosive service

Method- Roll Bonding

Roll bonding is a diffusion-based method that uses heat and pressure to bond two or more metal plates. The process typically involves stacking cleaned layers of stainless steel and carbon steel, heating them, and passing them through rollers under high pressure.

How It Works

During hot roll bonding, the combination of temperature and compression causes the metals to undergo plastic deformation. At the interface, significant plastic flow and atomic diffusion occur. This produces a clean, smooth, and strong metallurgical bond.

If the rolling takes place in a vacuum atmosphere, the process ensures a clean and dense interface free from oxidation or impurities. This version is known as vacuum hot roll bonding and is commonly used to produce high-quality stainless steel clad plates.

Advantages

High Production Efficiency

Roll bonding supports continuous and automated production, making it suitable for large-volume manufacturing.

Excellent Surface Flatness and Finish

The bonded plates have consistent thickness and a smooth interface, ideal for further fabrication and forming.

Consistent Quality

The process offers tight dimensional tolerances and uniform bonding, ensuring reliability across batches.

Cleaner Metallurgical Interface

Vacuum control during rolling leads to cleaner and stronger bonds without voids or delamination risks.

Improved Process Flexibility

Recent innovations allow the addition of transitional layers at the bond interface. These layers reduce elemental diffusion and enhance interface strength and plate shape.

Limitations

Due to equipment capacity, roll bonded clad plates are generally limited to thicknesses ranging from 0.5 mm to 50 mm. For larger or thicker plates, alternative methods like explosion welding is preferred.

Applications of Roll-Bonded Stainless Steel Clad Plates

Chemical processing equipment

Evaporators and distillation towers

Storage tanks

Fugo is a professional manufacturer specializing in high-quality stainless steel clad plates designed for demanding industrial applications.

If you have any related needs, please contact:

Email: xgb@fugo-tech.com

Tel: 152-6182-0011

www.fugo-clad.com